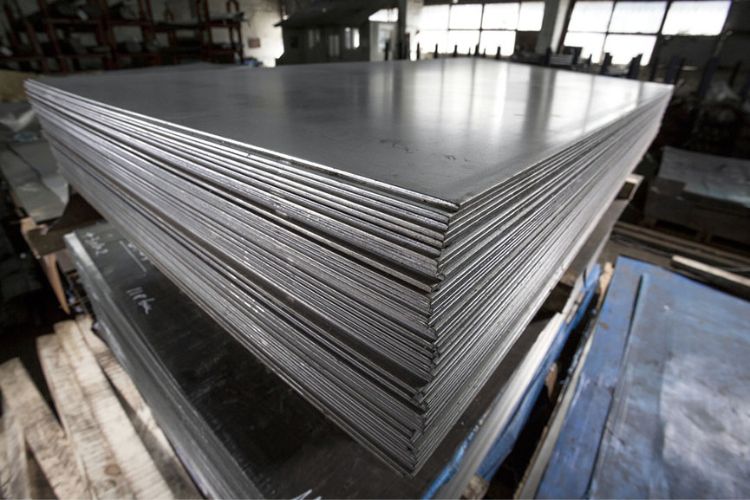

Stainless steel comes in different grades, and the two most common are 316 and 304. Though nearly identical in appearance to the naked eye, there are some key differences in the characteristics and, therefore, benefits of each metal grade.

Stainless Steel Grade 304

Definition of 304 Grade Steel

Grade 304 stainless steel is one of the most commonly used stainless steels in fabrication. The weldability and formability of 304 grade steel do not come at the expense of durability or toughness. This mixture of flexibility and strength makes it a popular choice for stainless steel fabrication.

Properties of 304 Grade Steel

Chemical composition:

- Carbon: <=0.08%

- Chromium: 18–20%

- Iron: 66–74%

- Manganese: <=2%

- Nickel: 8–10.5%

- Phosphorus: <=0.045%

- Sulfur: <=0.03%

- Silicon: <=1%

- Physical composition:

- Ultimate Tensile Strength: 85 ksi

- Yield Strength: 35 ksi

- Shear Modulus: 11,000 ksi

- Shear Strength: 56 ksi

- Fatigue Strength: 37.5 ksi

Applications of 304 Grade Steel

There are a variety of products and equipment that can be made from 304 grade steel, including:

- Stainless steel benches

- Commercial kitchen layouts

- Surface for food preparation

- Bars

- Food processing.

Pros and Cons of 304 Grade Steel

Pros:

- Easy to clean and maintain: Grade 304 steel doesn’t require special cleaners and is naturally antibacterial, making it one of the best alloys for food preparation, medical facilities and laboratories.

- Strong and durable: 304 grade is a popular choice for benches, kitchen surfaces, bars and more because it is extremely tough and durable.

- Versatile: One of the reasons 304 grade stainless steel is so popular is that it is a very versatile material that can be made into a wide range of products and equipment. It is suitable for both outdoor and indoor purposes and does not corrode unless it is exposed to particularly harsh chemicals or it is used in and around marine environments for long periods of time.

Cons:

- Higher initial price: The initial price of 304 grade stainless steel is higher than some other stainless steel. However, in the long run, this initial investment will pay off in durability and reliability. It’s more affordable than 316 grade steel.

- Not marine grade: 304 grade is fantastic for environments like kitchen and medical facilities but isn’t as effective as 316 for marine purposes.

- Non-magnetic: This is usually not an issue, but it is worth noting if you require a magnetic surface.

Stainless Steel Grade 316

Definition of 316 Grade Steel

This composition of steel was initially created to be used in paper mills, but it has since become more widely used in a variety of industries. Nowadays, it is sometimes referred to as marine-grade stainless steel due to its superior performance and endurance in saline environments.

Properties of 316 Grade Steel

Chemical composition:

- Carbon: <=0.08%

- Chromium: 16–18%

- Iron: 66–74%

- Manganese: <=2%

- Nickel: 10–14%

- Phosphorus: <=0.045%

- Sulphur: <=0.03%

- Silicon: <=1%

- Physical properties:

- Ultimate Tensile Strength: 82.2 ksi

- Yield Strength: 36.6 ksi

- Sheer Modulus: 11,000 ksi

- Shear Strength: 58 ksi

- Fatigue Strength: 30ksi

Applications of 316 Grade Steel

There are a variety of products and equipment that can be made from 316 grade steel, including:

- Laboratory equipment and benches

- Food processing equipment

- Marine equipment

- Storage tanks.

Pros and Cons of 316 Grade Steel

Pros:

- Marine grade: Ideal for harsher, more corrosive environments, such as salt water and salt air.

- Stronger than 304: 316 grade steel is stronger than 304, making it ideal for harsher environments.

- Corrosion resistant: 316 is extremely corrosion resistant, making it great value in more demanding areas.

Cons:

- Requires the right tools to fabricate: To bend, mould and work with 316 grade, you’ll need the right equipment and the skills to use them.

- Expensive initial costs: 316 grade steel costs more than 304 steel, and, therefore, is only used when there’s a clear advantage, such as in or near saltwater environments.

- Less formable than 304: 316 doesn’t offer the same level of fabrication flexibility as 304 does.

Cost Comparison of 304 and 316 Grade Steel

The biggest factor in determining the price of stainless steel is the alloy makeup of the material. Every grade of stainless steel requires a minimum of 10.5% chromium and is alloyed with iron. This makes up a huge proportion of any stainless steel. However, nickel is what makes 304 and 316 more expensive than other grades of stainless steel. Because 316 has more nickel in it, it is, therefore, more expensive than 304.

Corrosion Resistance of 304 and 316 Grade Steel

One of the biggest selling points of stainless steel as a material is its strength and resistance to rust, oxidation and corrosion. Both 316 and 304 stainless steel offer excellent corrosion resistance due to their nickel content. However, 316 grade stainless steel also contains molybdenum, which improves its corrosion resistance in harsher environments. This makes 316 grade steel the ideal choice for any highly corrosive environment.

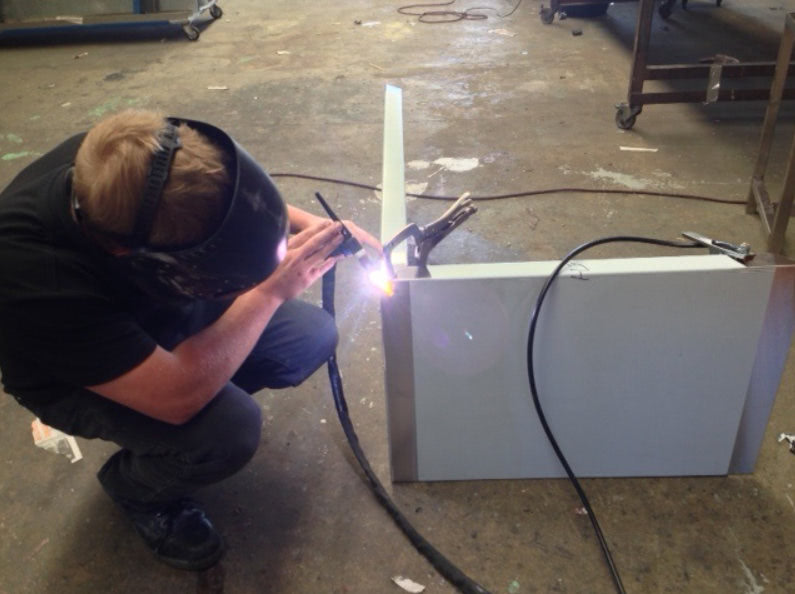

Welding of 304 and 316 Grade Steel

304 is slightly easier to weld and is more formable, making it more versatile to fabricate into a wide range of products. 316 grade steel requires specialised equipment to weld, but with the right tools and skill set, it can be fabricated into various components and products.

Heat Treatment of 304 and 316 Grade Steel

The application of heat treatment is a common process with all stainless steel, including 304 and 316 grade steel. Heat treatment won’t harden austenitic steels, such as 304 and 316 grade steel. It can, however, increase corrosion resistance and reduce the steel’s hardness.

Maintenance of 304 and 316 Grade Steel

Both stainless steel grades are antibacterial and easy to clean, usually without the need for chemicals. Read our guide to caring for stainless steel benches for more information.

Martin Stainless Steel is Here for Your Stainless Steel Fabrication Needs!

Still not sure what the best stainless steel grade is for your project? That’s where we can help! The expert Martin Stainless Steel team has over three decades of experience in stainless steel fabrication.

Whether it’s a stainless steel bench or an entire kitchen layout, our team can create the perfect product for your home or business. Get in touch today for a quote or to discuss your next project.